SOLUTIONS

SOLID WASTE DISPOSAL MACHINE

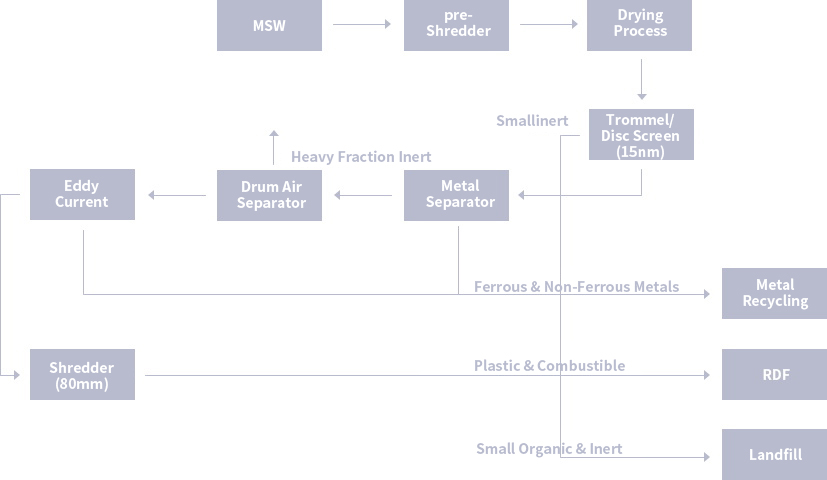

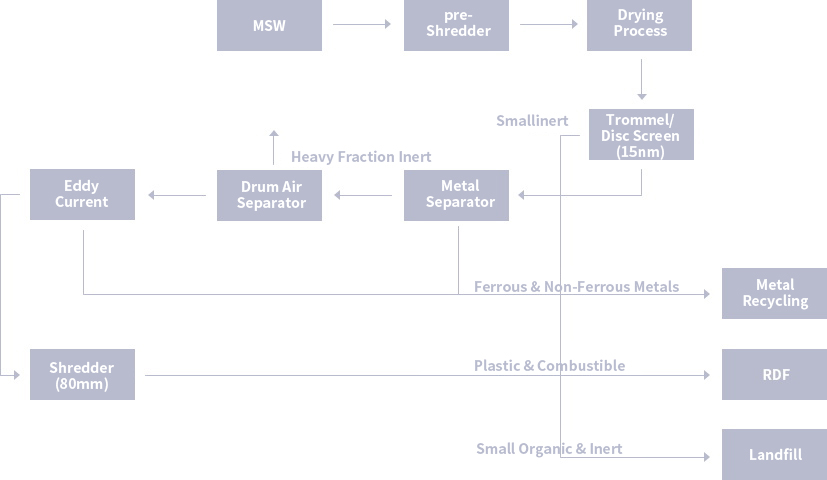

The main purpose of this process is to separate the raw waste into: combustible fraction (to produce RDF – refuse derived fuel), recyclables (ferrous and non-ferrous metals), and the remaining inert fraction (landfill). The plant is designed to process mainly municipal solid waste (MSW) but is able to process a wide variety of waste such as landfill waste or industrial waste. The plant is solid, compact and versatile providing reliable commercial operation. The main product is the high quality fuel (RDF) produced for the purpose of energy recovery in the power plant. This energy is recovered with high efficiency in the form of electricity.

- SPECIFICATIONS

- MAIN EQUIPMENTSVIDEOS

- VIDEOS

SYSTEM LAYOUT

1. Pre-treatment

● MSW reception

● Presorting – separate all unshreddable or hazardous objects

2. Biological treatment – moisture content reduction in order to

● meet the off-taker expectations

● enable more efficient mechanical treatment

● enable to use organic fraction as an additional source of energy

3. Post treatment

● Metal separation

● Inert material separation/screening

● Size reduction to meet the off-taker specification

RDF stands for Refuse Derived Fuel and can be considered as any combustible material derived from waste.

Potential users: Cement Industry Solid fuel fired power plants

Dust fired power plants Gasification plants

Lime Industry Iron Plants

Advantages of using SRF:

♦ Solve environmental problems at landfills such as: greenhouse gases emissions, leachate emissions to the ground, ground water contamination

♦ Locally produced (no import needed), save fossil fuels

♦ High calorific value (1 ton of coal can be replaced with 1.3 ton of SRF)

♦ Easy to handle and feed to the burner

CASES

-

产量:40 t/h

投产时间:2014

MSW Separating Line

-

产量:40 t/h

投产时间:2014

MSW Separating & Crushing Line

|

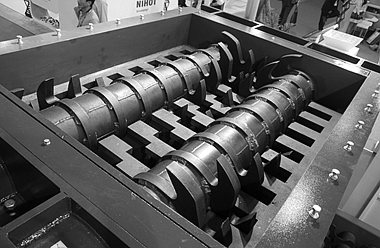

Pre-shredderThe front loader/grab loads the material onto the feeding conveyor that feeds the pre-shredder. The pre-shredder cuts and isolates the material into pieces less than 300 mm thus enabling the subsequent process to perform optimally. The pre-shredder is designed for industrial purposes. This high capacity machine is driven by hydraulic unit to run the two slow turning rotors and has many features to ensure reliable and economic operation. Hydraulic drive gives consistent high torque at any speed of the rotors and enables to stop the machine immediately in case of any un-shredable material occurs in the machine. This feature protects the shredder from damages. |

|

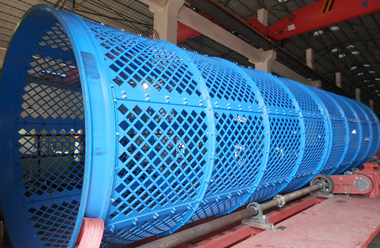

Trommel (separation by size)The dried waste is fed into the drum screen (trommel) where the fine fraction containing mostly non-combustible materials such as sand and glass, are screened out. The drum screen is 8 meters long, has a diameter of 2.2 meters. When the declined drum rotates, the material inside slides down and forward. Particles smaller than a defined size (approximately 20 mm) are screened through the perforated sheet metal surface of the drum. Non-combustibles drop down to a bunker and are removed by front loaders. The combustible fraction is discharged from the other end of the drum to continue the process. |

|

Metal SeparatorA strong magnet separates the ferrous metals from the material stream. The separated particles are guided via a chute to a container below and will be sold as recyclable metal. The separator can be over belt magnet or magnetic roller. |

|

Eddy Current (non-ferrous metals separation) - optionThe flow of material from the air classifier (the position depends on the waste composition and should be customized) is fed to the eddy current separator. The eddy current separates aluminum and remaining conductive metals as well as remaining ferrous metals. The separation is extremely effective due to the fact that the incoming material stream is very dry and evenly fed. |

|

ShredderThe shredder cuts the material to a size of 50 - 80 mm (where necessary, this can be adjusted by changing the bottom screens). In case any un-shredable materials, like reinforced cement blocks, are detected, the shredder stops automatically. The working principal is similar to the pre-shredder as both machines are hydraulically driven. The shredded material - RDF is discharged from the shredder by means of a chain conveyor. |